30+ Years of Experience

Lex Technoaid has been serving the Machine Tool, Automotive and Aerospace industries since 1994.

Our Founding Chairman and Managing Director,

Mr. Sivasubramanian S has been with the Machine Tool Industry since 1981, building a solid foundation for the company.

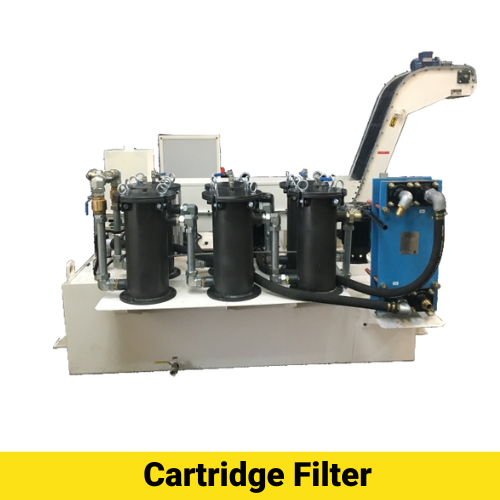

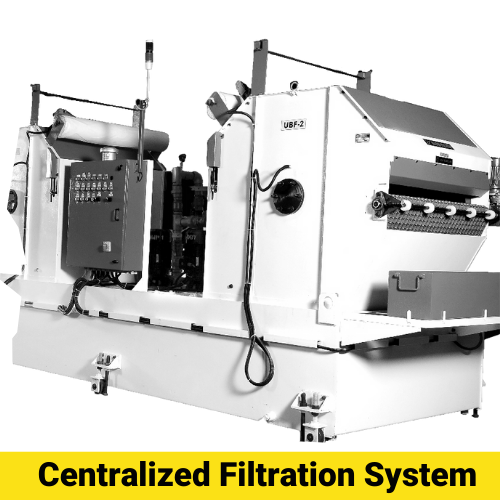

These systems are specifically designed to filter coolant upto 10 Microns or finner. The setup typically includes cartridge filters, bag filters or Compact Band Filters depending upon the volume of chips generated and level of filtration required.

The high pressure pump in Through Coolant System supplies clean coolant through the spindle with the desired flow and pressure.

ADVANTAGES

This system has two cartridge filters

Hydraulic Oil Chillers are used to maintain precise temperature of oil used in hydraulic systems of machine tools, high speed presses, Special Purpose Machines and other hydraulically operated equipments.

The performance and set parameters are maintained by retaining consistent oil viscosity and constant temperature. Lex manufactures Chillers with zero percent ODP (Ozone Depletion Potential) that are environment friendly.

Coolant Chillers help to maintain precise temperature by eliminating the excess heat added during machining process and pumping.

These Chillers are available in Stand Alone and Dip -in (immersible) types.

Lex manufactures Chillers with Zero ODP (Ozone Depletion Potential) refrigerant which are environment friendly.

Increased tool and coolant life.

Helps to achieve consistent component accuracy.

Can be suitably designed for closed loop and open loop applications

Available for capacities between 0.3 to 100 tons.

Centralized Chillers can serve multiple machines.

Water Chillers are ideal for Spindle Cooling, Induction Hardening, Injection Moulding, Laser Cutting, Laser Marking, Laser Welding, 3D Printing and other applications .

A properly sized Centralized Water Chillers can supply chilled water to multiple machines simultaneously.

Lex manufactures Water Chillers with zero ODP refrigerants which are environment friendly.

Contact Us

Shed No.1, Badrappa Industrial Estate, Kamakshipalya,

Bengaluru, INDIA - 560079.

Email : marketing@lextechnoaid.com

+91 9916698105

+91 9739390655